Manufacturing

KEY INSIGHT

Technological advancements in manufacturing have provided a major growth in production capacity and efficiency. Unfortunately, the electronic components that make these advancements possible are also highly susceptible to failure and misoperation caused by transient voltage. In fact, 35% of all lost production hours can be attributed to problems related to transient voltage. The good news is implementing a Maxivolt transient voltage mitigation system eliminates this downtime and enables plants to realize the efficiency and capacity improvements they invested in.

THE CHALLENGE

An optical communications equipment manufacturer contacted Maxivolt needing a solution to improve their equipment’s operational availability. The client specified that over the past year, component failures due to transient voltage had cost them $79,940 in replacement part expenses. Additionally, individual machine downtime due to these events was 70 days. They were unable to quantify the cost of lost production due to downtime, so this case study focuses only on the impacts on replacement part expenses.

THE SOLUTION

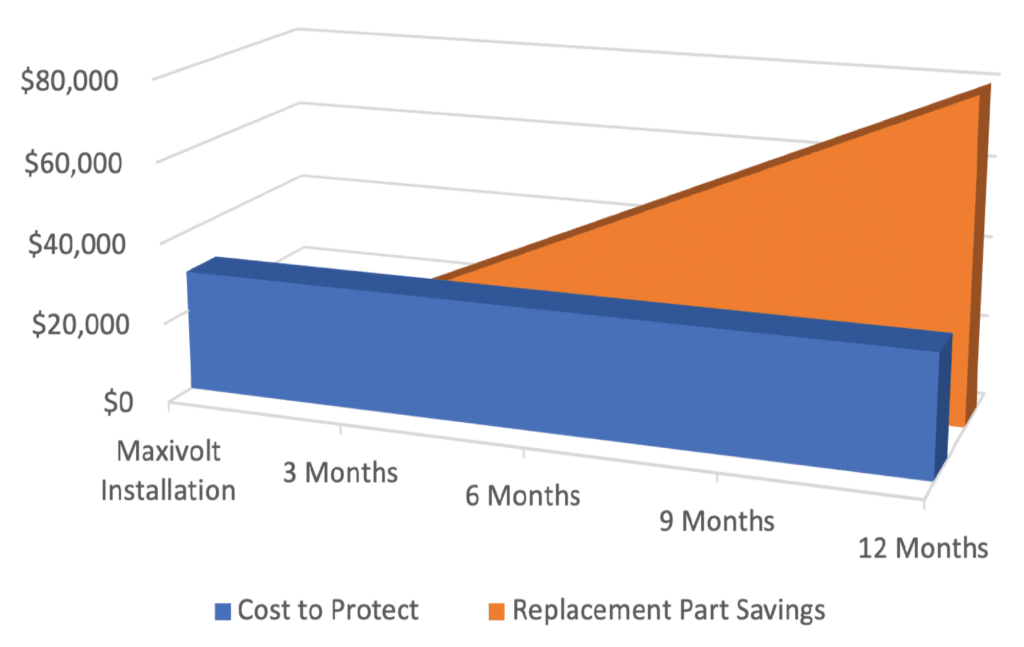

Through phone and email correspondence and an on-site electrical system evaluation, Maxivolt and the client developed a strategy to minimize component failure and equipment downtime due to transient voltage. Maxivolt devices were installed according to this strategy at a cost of $29,995. A system was put in place to track component failures and replacement part expenses.

THE IMPACT

One year after installing Maxivolt devices, the client reported replacement part expenses due to transient voltage reduced from $79,940 to zero. The $29,995 investment paid for itself and started providing a return in less than five months in saved replacement part expenses alone. This figure does not include returns based on averted lost production, material waste, and other related benefits.