Water Production

KEY INSIGHT

Reliable groundwater production is mission-critical to many communities, industrial operations, and other establishments. Replacing a downhole pump is typically a painful and expensive process. In many cases, it can interfere with or even halt critical operations. Mitigating damage caused by transient voltage with a Maxivolt engineered solution can reduce pump failure and misoperation by up to 80%. More reliable groundwater production means fewer headaches, reduced maintenance expenses, and more resources for other endeavors.

THE CHALLENGE

A mid-sized groundwater production operator was experiencing downhole pump failures due to transient voltage. They attempted to resolve the issue by installing a popular brand of surge protective device at each of their well sites. Despite this effort, pump failures persisted. The operator’s average cost to pull, replace, and reset a downhole pump was $60,000. They estimated lost revenue due to downtime resulting from these failures was equal to the cost of replacing the equipment.

THE SOLUTION

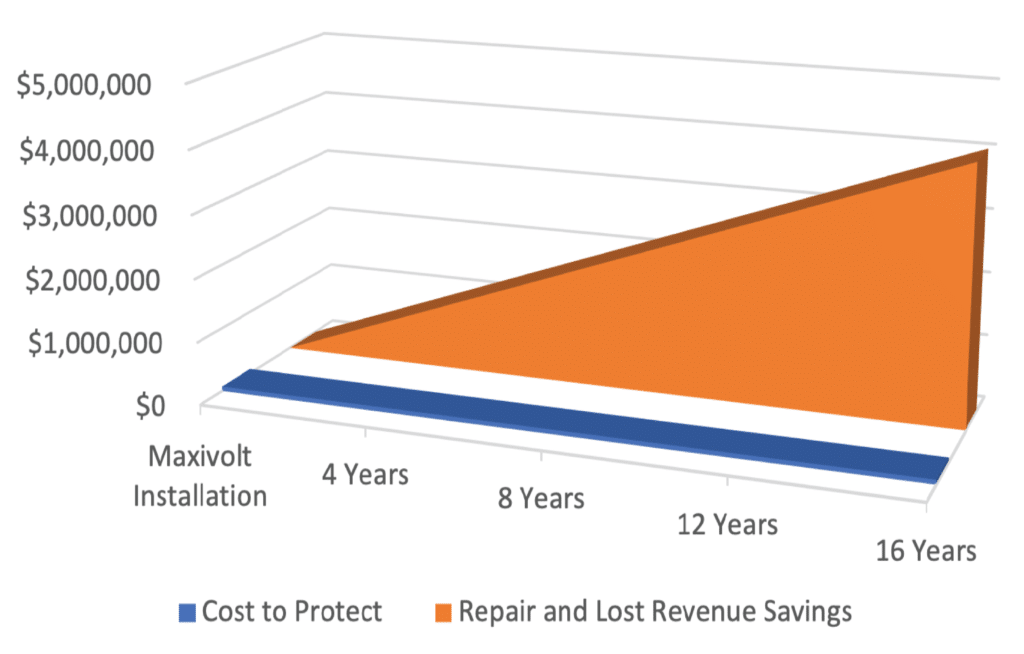

Maxivolt conducted on-site power quality evaluations at multiple groundwater production well sites and developed a transient voltage mitigation strategy for the well field. The operator installed Maxivolt devices in accordance with this strategy at a cost of $71,245. They also developed a system to track pump failures as well as Maxivolt device and fuse expenditures.

THE IMPACT

Over 16 years after installing Maxivolt devices, the operator reported zero pump failures due to transient voltage. In the same time frame, 68 fuses on the Maxivolt devices were blown and replaced. Using an average of two blown fuses per event, there were an estimated 34 major events that were capable of causing downhole pump failure. Each avoided failure saved the operator $120,000 in repair costs and lost revenue.